Description

Super-Pozz® is a highly reactive alumino-silicate pozzolan. The product’s

pozzolanic activity ensures increased strength and durability, whilst the unique

particle size distribution and spherical shape makes it the preferred material where

improved workability and/or water reduction is required.

Uses

»High-performance concrete with a low w/c ratio, high early and later age

strength and superior durability are made possible with the inclusion of

Super-Pozz® in the mix

»Super-Pozz® can be used in the production of Self Compacting Concrete (SCC)

»Low w/c ratio Super-Pozz® concrete exhibits decreased permeability, reduced

Sulphate Attack and reduced Alkali Silica Reactivity (ASR)

»Reduced shrinkage. The lubricating action of Super-Pozz® reduces water

content and drying shrinkage

»Excellent cost in use solution for the production of all high strength

Readymix, Precast or Site-batched concretes

Advantages

»Improved rheology with better cohesion, ensures no bleed or segregation

significantly improving the placeability of the concrete

»Pozzolanic properties ie Super-Pozz® has the ability to react with lime,

ensures more efficient hydration and improved strength development over time

»In applications where durability is a key requirement, the dense paste

matrix resulting from Super-Pozz® addition actively decreases permeability

thereby reducing the destructive effects of chloride and sulphate attack

»Super-Pozz® concretes are easily pumped and provide a blemish free surface

finish

Quality Assurance

Micron Materials™

products are manufactured under a Quality Management System which conforms

to the requirements of ISO 9001: 2000. The Quality Management System is

registered and audited by SANS.

Technical Support

Micron Materials™ provides a technical advisory service for on-site assistance

and advice on mix designs, evaluation trials and storage/handling of Super-Pozz®.

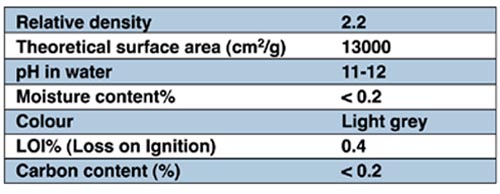

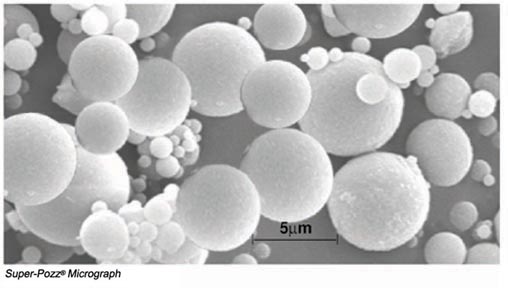

Characteristics

Physical

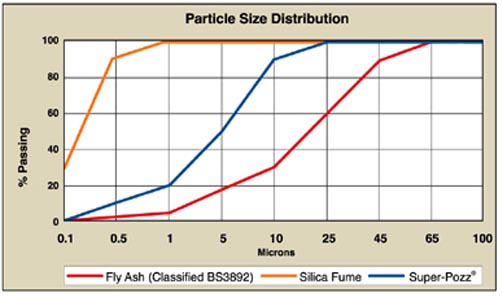

The mean particle diameter of Super-Pozz® typically ranges between 3.9 and 5.0

microns with over 90% of the material having a particle diameter of less than

11 microns. Whilst Silica Fume is finer, it is predominantly single sized.

Super-Pozz®, in relation, with it’s bi-modal distribution effectively fills

the void spaces between fine aggregates and cementitious component creating an

ideal ‘fine filler affect’. This feature is particularly beneficial in high

consistence and Self Compacting Concretes.

Chemical

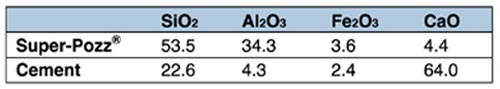

Super-Pozz® has a similar chemical composition to Portland Cement being made up

of the same basic components but in differing proportions and minerology.

Portland Cement is rich in Lime (CaO) while Super-Pozz® is low. Super-Pozz® is

high in reactive silicates while Portland Cement has smaller amounts.

Typical chemical compounds

The high silica content and sum of the oxides are similar to a Fly ash

designated as BS 3892 Part 1. Through pozzolanic activity, Super-Pozz®

combines with Ca(OH)2(C-S-H) to produce the same

cementitious compounds(CSH) formed by the hydration of Portland Cement.

Hydration reaction

Cement + H2O

= Calcium silicate hydrate (CSH) + Ca(OH)2

Ca(OH)2 + Super-Pozz®

= CSH (additional, durable cement gel)

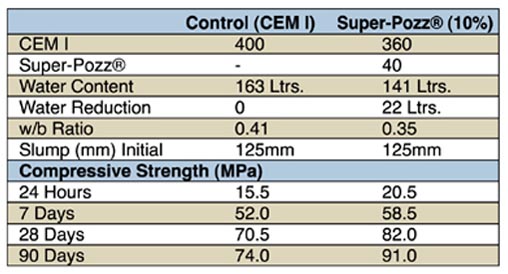

Typical performance properties

Water reduction

Values obtained for concrete with equal binder content (400kg/m3),

equal HRWR dosage and constant workability

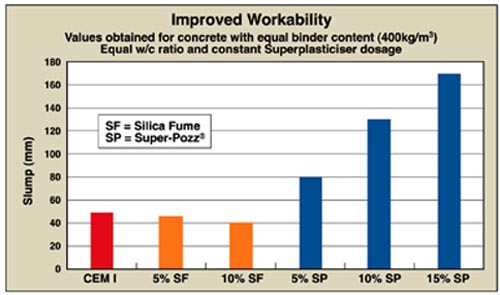

Workability

Though never specified, workability is one of the most critical characteristics

for fresh concrete. Workability refers to the ease of handling, placing and

finishing of the fresh concrete. Approximately 30 litres of water is required

to hydrate 100kg of cement. A normal concrete mix will generally need up to

twice this amount of water, the additional water being required to facilitate

handling and placing. This “water of convenience” not only increases the

water/cement ratio, requiring more cementitious binder to achieve the design

strength, but also increases the possibility of segregation. Super-Pozz®

addition actively reduces the water demand of the concrete mix giving rise to

high strengths and superior cohesion at higher workability levels, without the

requirement for additional water.

Compatibility

With other cementitious materials

and admixtures

Super-Pozz® is suitable for use with all types of Portland Cement and cement

replacement materials eg. GGBS, Fly Ash (Pfa), Micro-silica and Meta-kaolin.

Super-Pozz® is compatible with a wide range of admixtures working particularly

well in high performance concretes when used in conjunction with

superplasticisers.

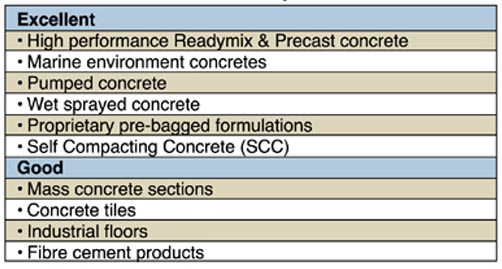

Applications

Concretes containing Super-Pozz® can be used in virtually any application where

Portland Cement concretes are used. With its unique properties, it is

particularly suited for high performance applications including the manufacture

of proprietary pre-bagged repairs, precision grouts and flowable screeds.

In marine environment concretes, and in any other application where durability

is a fundamental requirement, Super-Pozz® is the preferred addition to the mix.

Recommended uses of

Super-Pozz® Concretes

Addition rates and handling

Typical addition rates of Super-Pozz® in concrete range between 3 - 15% by weight of the cementitious content of the mix.

(For additional rates outside this range, please consult

Micron Materials™ Technical Department) The perceived higher cost of

Super-Pozz® addition can often only be properly evaluated against the dramatic

improvements in long term performance and low maintenance costs. Deciding on

the most suitable Super-Pozz® content depends on a number of factors including

design strength, placing method and durability requirements. To achieve the

optimum benefits of Super-Pozz®, proper curing in line with good concrete ‘practice’ should always be followed.

Super-Pozz® can be handled in terms of batching, mixing and delivery of

concrete in exactly the same way as cement using the same equipment.

In dry powder form, Super-Pozz® can be kept in a storage silo, however it is

often recommended that an aeration system be installed to facilitate easy

discharge from the silo. For advice on Super-Pozz® handling please consult

Micron Materials™ Technical Department.

Mix Design

When using Super-Pozz® in concrete, normal mix design procedures and guidelines

can be used taking into account the unique benefits and properties allowed by its addition.

Fresh Concrete Properties

Performance

Super-Pozz® imparts physical as well as chemical benefits when used in concrete.

In fresh or plastic concrete, the spherical shape and ultra-fine particle size

of Super-Pozz® significantly improves the rheology of the mix. As a result:

»the water content of the concrete can be reduced. As a guide the mix water

should be reduced by a minimum of 10%

»the workability of the concrete is improved at the same water content

without bleeding or segregation of the mix normally associated with highly workable concrete

»pumpability is greatly increased by the use of Super-Pozz®

and it is often possible to pump mixes without altering the fine aggregate

content. In more conventional concretes the coarse aggregate content can be increased eg. at a

Super- Pozz® addition of 15% an increase in stone content of ±5% can be achieved

»Super-Pozz® addition can lead to more cost effective dosage levels of

dispersing admixtures such as superplasticisers.

Hardened Concrete Properties

Strength Development

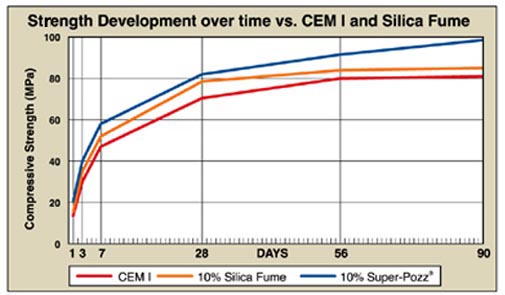

The typical strength development of concrete containing

Super-Pozz® is illustrated below

As can be seen from the above graph the mix containing Super-Pozz® has comparable strengths to Silica fume concrete at all ages. It also illustrates the continued strength gain up to 90 days due to the pozzolanic properties of Super-Pozz®.

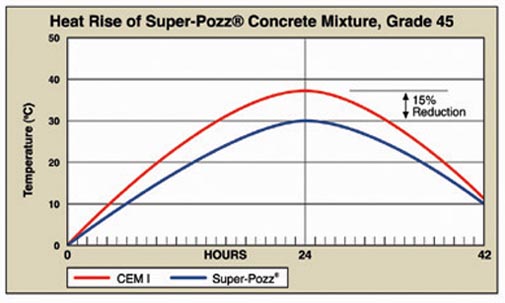

Heat of Hydration

Super-Pozz®, by reducing the water content with a subsequent reduction in the cement

content is very effective in the control of the heat of hydration. At Super-Pozz® addition

levels of between 10-15% reduction in the maximum temperature generated can be in the order

of 15%.

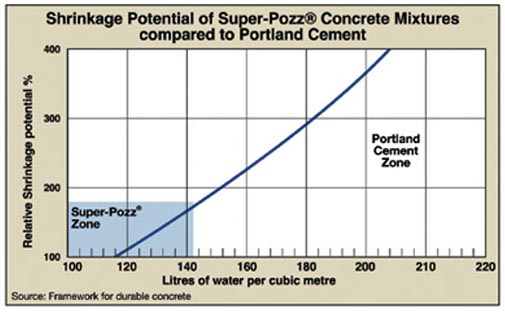

Relative Shrinkage Potential

The largest contributor to shrinkage is water content. Lower water demand Super-Pozz®

concrete can potentially reduce shrinkage by up to 75%.

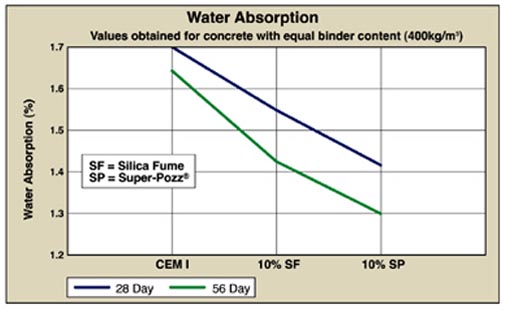

Water Absorption

The pozzolanic reaction of Super-Pozz®

in concrete produces additional Calcium silicate hydrate gel which fills

pore spaces. This results in a dense paste matrix. The decrease in water

absorption from 28 to 56 days reflects an increase in density as a result

of the refinement of the pore structure.

Durability

Super-Pozz® protects concrete in a number of ways. Hardened Super-Pozz® concrete is less

permeable because Super-Pozz®, unlike other high reactivity pozzolans reduces the amount

of water needed to produce a given slump. Coupled with its high pozzolanic reactivity,

creating more durable Calcium Silicate Hydrate (CSH) gel, Super-Pozz® reduces the rate

of ingress of harmful chlorides and other corrosive salts.

Chloride Ingress

The use of Super-Pozz® as a partial replacement of cement improves permeability thereby

significantly reducing both the diffusion and penetration of chlorides into the concrete.

In addition, research has shown that chemical binding of chlorides is improved by

alumino-silaceous pozzolans. The alumina content of Super-Pozz® exceeds 30%.

Sulphate Resistance

Super-Pozz® addition is an ideal means of providing Sulphate Resistance. Super-Pozz®

decreases the available sulphate thus preventing the formation of ettringite, which could

otherwise form expansive compounds.

Alkali-silica Reaction

Where aggregates cannot be classified as non-reactive,

Super-Pozz® has the ability to react with alkali hydroxides in Portland cement paste making

them unavailable for reaction with these aggregates thereby combating this expansive reaction.

Packaging

Super-Pozz® is available in Bulk (pressurised bulk powder tanker by road), 1-ton IBC’s or

Jumbo bags with plastic inner liner. The product is also available in 25kg plastic lined,

repulpable paper bags. Samples can be obtained from Micron Materials™

on request in buckets.

Storage

Super-Pozz® when stored correctly has an indefinite shelf life. Like cement,

Super-Pozz® must be protected from contamination and moisture. The product can be stored

in bulk in a clean, dry storage silo. Advice on aeration, which may be required due to the

product’s extreme fineness and rounded shape, is available from Micron Materials™ on request.

Health and Safety

Extensive testing has shown Super-Pozz® to be non-toxic and environmentally benign.

No known significant health risks are associated with Super-Pozz® but high concentrations

of dust may cause irritation. It is recommended that suitable protective clothing, gloves

and eye/face protection is worn. In case of contact with eyes, rinse immediately with

plenty of clean water and seek medical advice. For further details please consult the

Material Safety Data Sheet (MSDS) for Super-Pozz®.

Important Notice: Micron Materials™ products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions for the Supply of Goods and Service, copies of which may be obtained on request. Whilst Micron Materials™ endeavours to ensure that any advice, recommendation, specification or information is accurate and correct, it cannot, because it has no direct or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the use of its products, whether or not in accordance with any advice, specification, recommendation or information given.

PLEASE

NOTE:

The following information has been obtained from test results in an

accredited laboratory. Although the information is accurate, variation

in specific parameters might occur from time to time. No guarantee is

therefore given or implied and Micron MaterialsTM

disclaims any liability from damage or consequential loss.